Shredding is a treatment technology applicable to all materials from industrial waste to domestic waste, from agricultural and forestry waste to construction waste. In simple terms, shredding is the breaking down of waste into smaller parts. In today's world, the general trend of garbage disposal is "crushing and then sorting". Waste shredder reduces the size of the waste, makes transport easier. Efficient crushing makes sorting more efficiently in the next step, and effective sorting means greater opportunities for recycling.

Application of Waste Crushing Technology in Different Industries

Biomass Power Plant

Companies engaged in biomass processing are increasingly using shredders to increase the consistency of the final material, which can ensure efficient combustion of biomass fuel in the furnace, reduce gas emissions and improve thermal energy conversion efficiency. High-quality fuels after crushing are attractive to power plants keen to reduce their overall carbon emissions.

Waste Incineration Plant

How to recover as much energy as possible from discarded waste has become one of the primary concerns in the global waste management field. There are many technologies to produce fuel and energy from waste, and incineration is one of the most common methods. In order to maintain a stable flow rate, improve combustion efficiency, improve emissions and reduce costs, shredding of waste is necessary.

RDF Production Line

Waste is considered as a potential energy source. Most refuse-derived fuel (RDF) plants have specific requirements on double shaft waste shredder for good shredding capacity, particle size and operational reliability to ensure efficient production of high-quality products.

Cement Factory

The cement industry is an energy-intensive industry. The production of cement plants requires heat and electricity. Electricity is used to grind raw materials and finished cement. Thermal energy, mainly from coal, is consumed in kilns for the high-temperature treatment of limestone to produce clinker (cement raw material). More and more cement plants around the world will partially replace natural gas and coal with refuse-derived fuel (RDF) as fuel for cement kilns.

Landfill

No matter how large a landfill may initially appear, it will be filled up very quickly. Efficient shredding of waste makes the best use of the available space through a significant reduction in volume, which also facilitates further disposal of the shredded waste.

Garbage Transfer Station

Waste transportation costs are on the rise, and in order to save money, shred waste to a manageable size at or near the collection point. At the same time, the waste transfer station can be equipped with material waste recycling equipment and small mechanical biological treatment system, which can recover valuable materials from waste and perform preliminary pretreatment on mixed waste.

Recycling Center

In the recycling center, whether it is a single type of garbage or a mixed type of garbage, it is usually crushed before recycling, which can improve the recovery efficiency of materials. If separation is required, the crushed materials is more conducive to sorting. Crushing equipment is widely used in crushing construction waste and industrial waste.

Mechanical Biological Treatment Plant

A mechanical biological treatment system is a waste treatment facility that shreds waste for aerobic or anaerobic biological treatment. Mechanical biological treatment plants are often designed to treat mixed household waste as well as commercial and industrial waste.

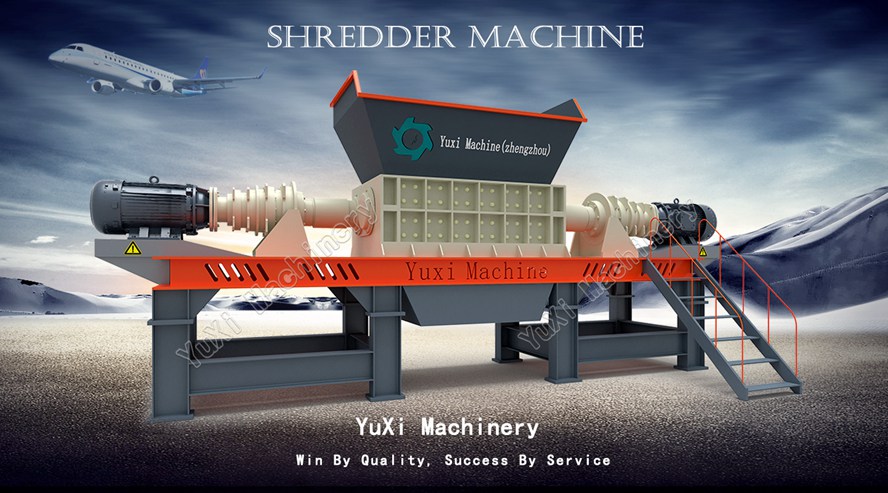

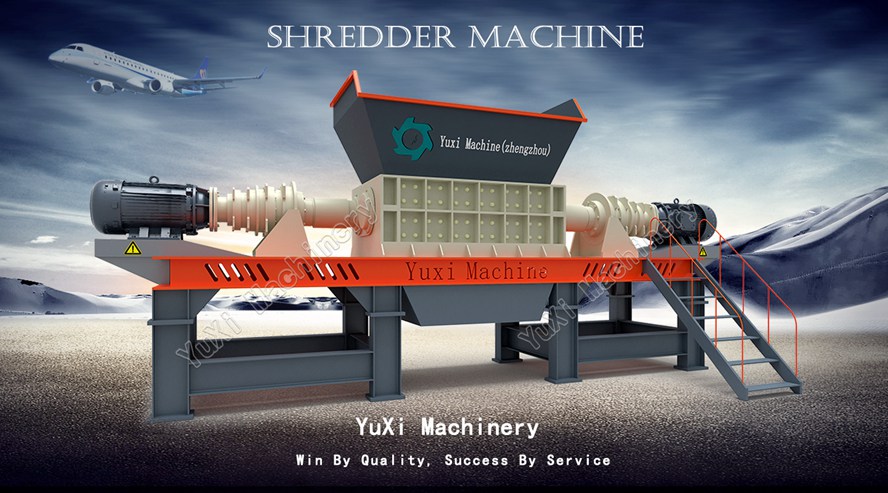

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment