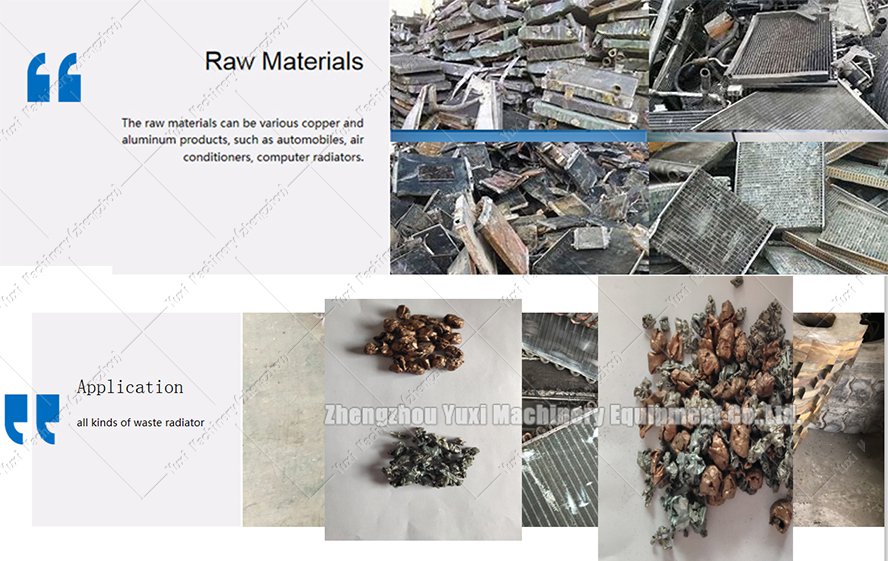

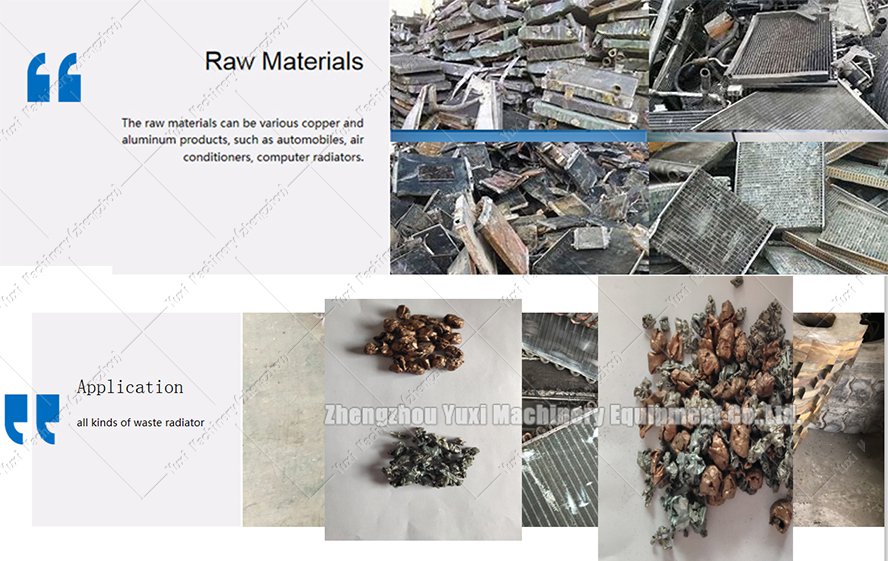

A large number of air-conditioning radiators, heating radiators, and automotive air-conditioning radiators are produced every year, which not only pollutes the environment but also causes a waste of resources. The radiators contain copper and aluminum, which are highly recyclable.

The copper-aluminum water tank is electronic waste. It is mainly composed of copper tubes and aluminum foil waste, and the copper content of red copper pipe can generally reach more than 97%.

How to Deal with Copper and Aluminum in Waste Radiators?

The main method currently adopted is to crush and then separate through the copper and aluminum radiator crushing and separating line. The separation effect reaches 99%, which is the current environmentally friendly recycling method. The copper-aluminum crusher can be used for trial use on copper-aluminum materials such as waste radiators, internal copper-aluminum waste water tanks, and motor rotors.

Copper-aluminum radiator crushing and sorting equipment is a set of production lines, which can process various large radiators and copper-aluminum water tanks or motor rotors below 15cm. The copper-aluminum radiator crushing and separating equipment has multi-purpose, and each stand-alone machine can also process many kinds of materials, therefore, it is a value-preserving production line.

The copper-aluminum radiator separator for air-conditioning radiators uses dry physical processing technology, which can quickly separate the copper and aluminum of the entire heat sink, requiring less labor, with no risk, large output, and one-key operation. Only 2-3 people is enough for operating the complete production line, and the production capacity is about 2 tons per day.

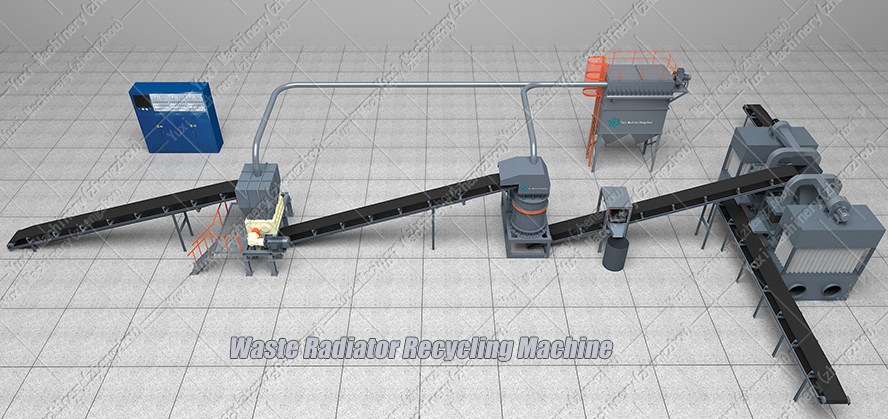

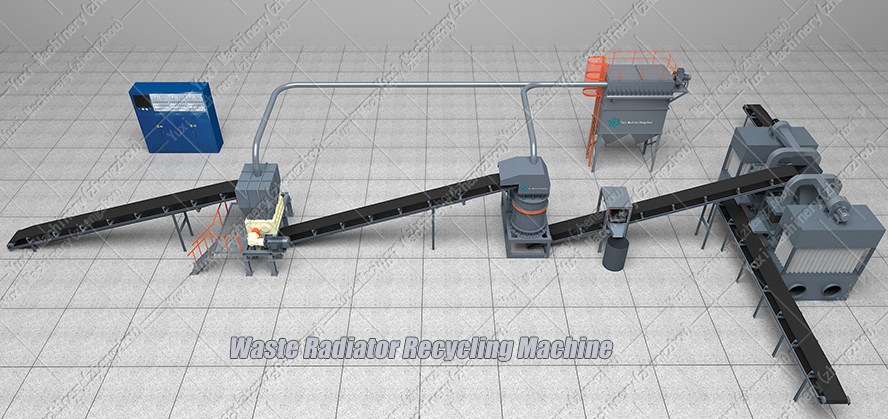

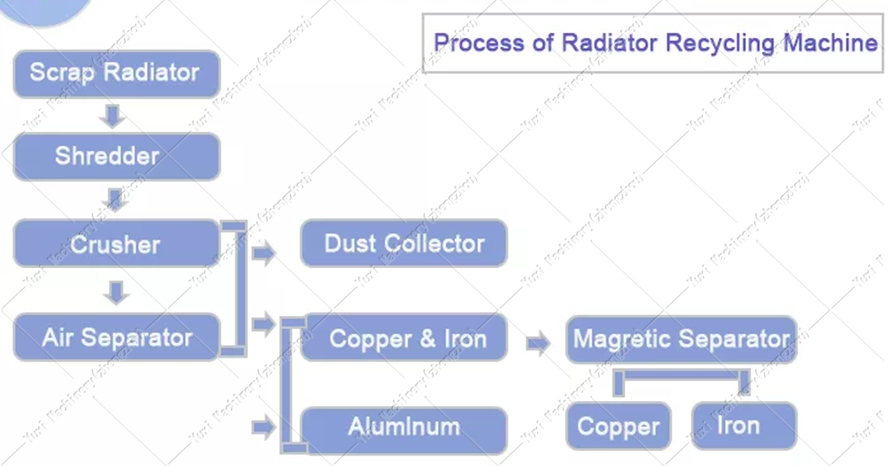

The copper-aluminum radiator crushing and separating line is composed of multiple stand-alone machines, and the production line is with conveying system, crushing system, sorting system, and crushing system.

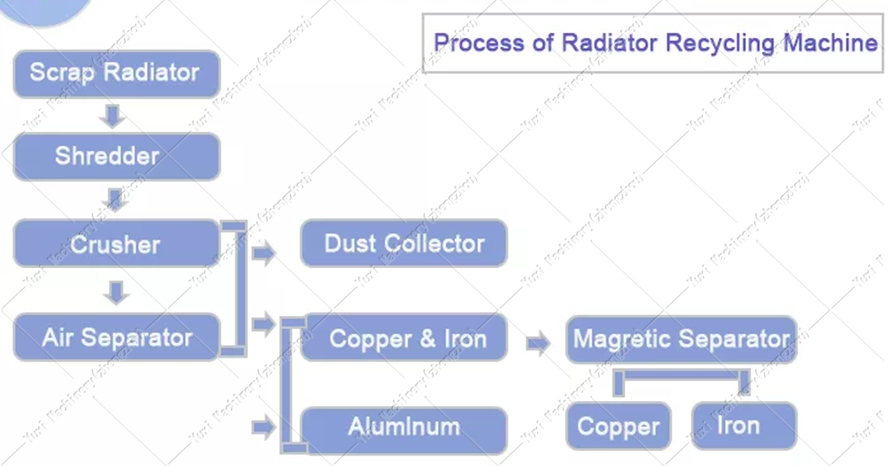

1. Generally, we design metal shredders and vertical crushers for two-stage crushing. The whole radiator goes in and is crushed into granular copper-aluminum mixture materials. The materials that can be processed by waste shredders and vertical crushers are even more diverse.

2. Granular copper-aluminum mixture materials are transported into the airflow specific gravity sorter. The inside of the sorter is equipped with a fan. Under the action of its own density and wind force, the lighter aluminum will fall to a farther place inside the airflow sorter. Under the action of airflow and vibration, the lighter material is on the upper layer, and the heavier material is on the lower layer. Under the action of vibration, the two materials with different weights flow separately to realize the separation of copper and aluminum.

Advantages of Yuxi Copper-aluminum Radiator Crushing and Sorting Line

1. The copper-aluminum radiators are coarsely crushed by the first crusher/finely crushed by the second crusher, crushed into materials with a length of about 3 cm, iron is separated by magnetic separation, and copper and aluminum are separated by two specific gravity separations.

2. The coarse crushing machine adopts the design of two shafts and rollers, which has low noise, high torque, and can crush large-volume radiators. The knives are made of alloy steel through special processing, with a service life of 8-16 months.

3. The fine crusher adopts high-speed hammer-type crushing, which has strong crushing capacity and can easily crush thicker iron and stainless steel frames. High degree of automation, only 1-2 operators are needed in the whole process.

4. Two-pole specific gravity separation is used to improve the separation accuracy. The purity of copper and aluminum can reach 99%. The crushing and sorting process is closed, and the dust collection system is equipped to effectively control the dust overflow.

The copper-aluminum radiator separation equipment really meets the needs of customers with large production volumes. The copper-aluminum recovery rate can reach more than 99%. The high purity of the sorted copper, aluminum and iron increases the recovery price and can also be directly processed. Under the general environment of energy saving, environmental protection and recycling of waste resources, Yuxi copper-aluminum radiator separation line also has a good market prospect and development space.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment