The whole car crushing line is designed for shredding, crushing and recycling scrapped car shells, scrapped motorcycles and bicycles, and other scrap metals. The metal materials after shredding can be directly recycled and smelted. It only takes several minutes to crush a whole car shell and complete the separation of metal materials, wires, rubber, and paint.

According to the needs of customers, Yuxi Machinery automobile crushing machine is more in line with the actual production needs of customers. At the same time, Yuxi Machinery designed the scrap car crushing plant considering the processing output, site size, and reasonable production line configuration, so that users can obtain the automobile crushing and separating line with best cost performance under the condition of effective cost input.

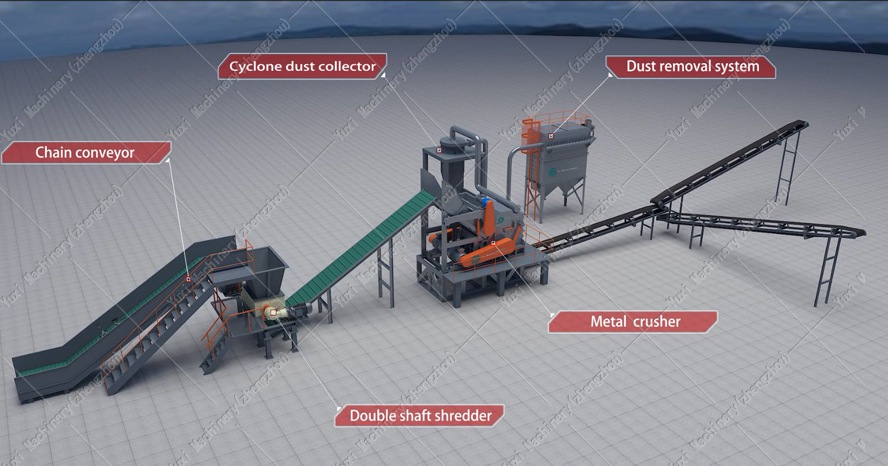

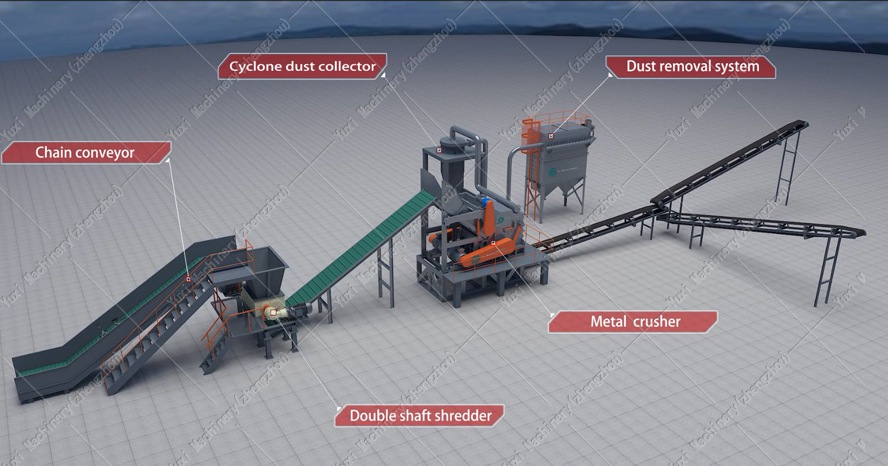

Working Process of Scrap Car Crushing Line

Scrap car shells are pre-crushed by a heavy-duty double-shaft shredder, and then secondary crushed by a metal crusher, and the paint and dirt on the surface can be cleaned. When car crushing machine is working, dust removal equipment collect oil paint, debris and other sundries. After secondary separation by magnetic separation equipment and eddy current separation equipment, and finally through the screen, the separation and recovery of all materials are completed.

The automobile shell crushing production line has the advantages of large processing capacity, good economic benefits and low maintenance cost, and the equipment has been well received by customers.

The waste car shell crushing and separating line is composed of heavy-duty double-shaft crusher, scrap steel crusher, feeding device, magnetic separation equipment and dust removal system. The car shell crushing line is mainly used for the crushing and recycling of large metal items such as discarded automobiles, automobile casings, aluminum alloy accessories, scrapped household appliances, scrapped motorcycles and bicycles.

Main Equipment in Scrap Car Crushing Process

1. Large chain plate conveyor belt: complete the feeding, conveying, stacking and other work of metal materials.

2. Double-shaft shredder: for first-level shredding of used cars.

3. Scrap metal crusher: secondary crushing of primary crushed metal material.

4. Magnetic separator: separates scrap metal materials.

5. Eddy circuit sorting machine: sorting aluminum alloys from metal mixtures.

6. Dust removal equipment: dust reduction and dust prevention of work site.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment