1. Made into new tires

The use of waste tires is mainly the retreading and comprehensive utilization of old tires. Retreading waste tires can not only benefit the protection of the environment, but also have many benefits, which can save resources and effectively reduce production costs and save social energy.

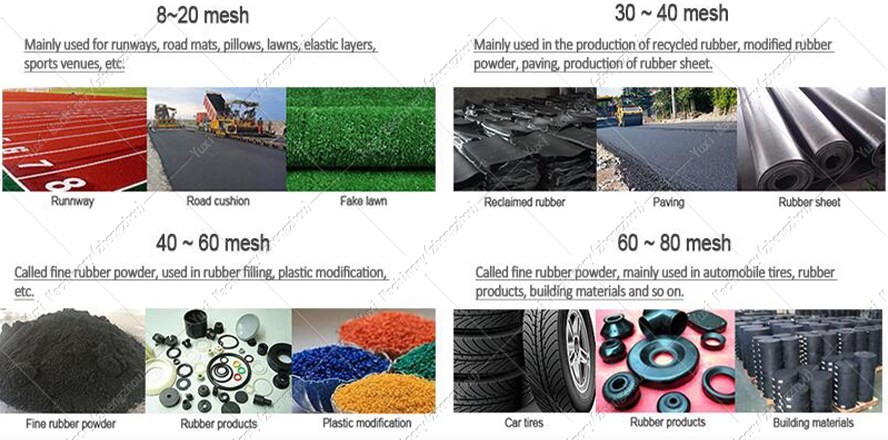

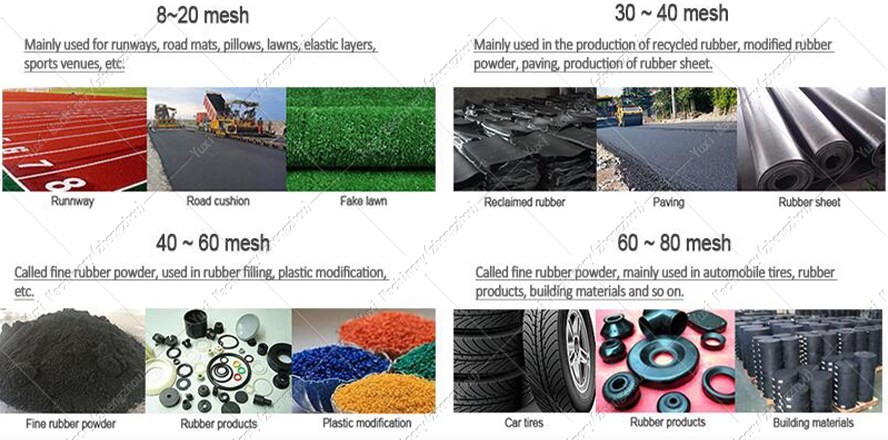

2. Made into rubber powder

Rubber powder is a powdery substance obtained by mechanically pulverizing waste tires by waste tire shredder. Generally, the main production processes are low-temperature freezing crushing method, normal temperature crushing method, water impact method, etc. The production of recycled waste tires into rubber powder is concentrated the integration of environmental protection and resource recycling. The former reason, which has led to the abandonment of the production of reclaimed rubber in developed countries, which has shifted the center of waste tire utilization to rubber powder and opening up other areas of utilization.

3. Used for filling of building

In recent years, waste tires have been widely used in civil engineering. Normally, the entire tire is processed into medium pieces. Under the same weight, the unit volume of broken tires has only reached one-third of commonly used backfill soil. As a result, the use of waste tires as building fillers produces much less overburden pressure than the use of soil backfill materials. For relatively weak foundations, it can effectively reduce the settlement of the foundation, and it can effectively enhance the overall stability of the house.

4. Restructured to other useful goods

The original shape of the used tires can be modified by bundling, cutting, punching, etc. to become very valuable items. Generally, the most common ones are the fenders, artificial reefs, and navigation marks that appear on the docks and ships, and floating lighthouses of lights.

5. Made into reclaimed rubber

The oldest method of comprehensive utilization of waste tires is to use certain chemical methods to desulfurize the rubber of waste tires to obtain the reclaimed rubber we need. At present, the internationally used reclaimed rubber production technologies mainly include microwave regeneration, Engel’s method, normal temperature regeneration method, radiation regeneration method, TCR method, low temperature phase transfer catalytic desulfurization method and extrusion regeneration method.

6. Thermal decomposition

The thermal decomposition of waste tires is to heat the waste at high temperature so that the old tires can be decomposed into combustible gas, oil, and carbon powder. The oil obtained after thermal decomposition is very similar to the commercial fuel we need. It can be burned directly or mixed and used with the fuel oil extracted from petroleum.

Small concluding remarks

For the utilization of waste tires, there is a long way to go, and I believe that we can completely solve this "black pollution" one day.

Yuxi Machinery is a large manufacturer of used tires recycling machines, feel free to leave us a message, thank you!

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment