With the rapid development of world economy, the accumulation of discarded tires and the pollution of discarded plastic bags and rubber products are also increasing. If processed, the utilization of these rubbers is very large. At present, the demand for rubber raw materials is showing a linear upward trend, and the gap between supply and demand continues to expand. Tire crushing separating plant can turn waste tires to rubber powder, so as to fill the demand for rubber powder and improve the ecological environment.

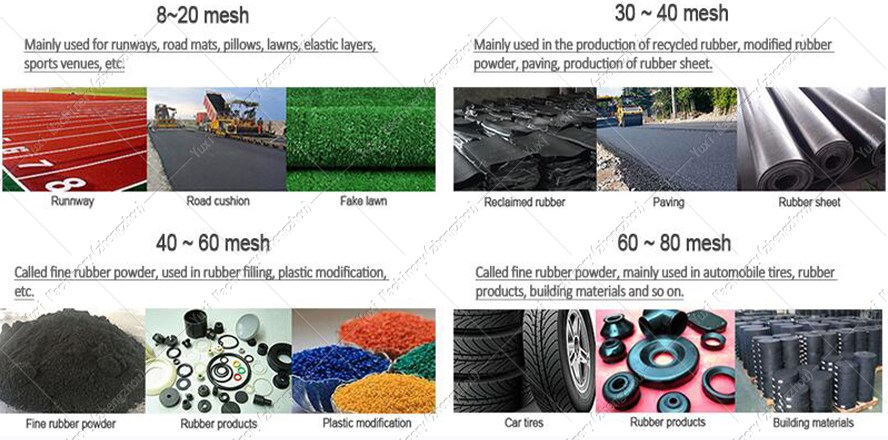

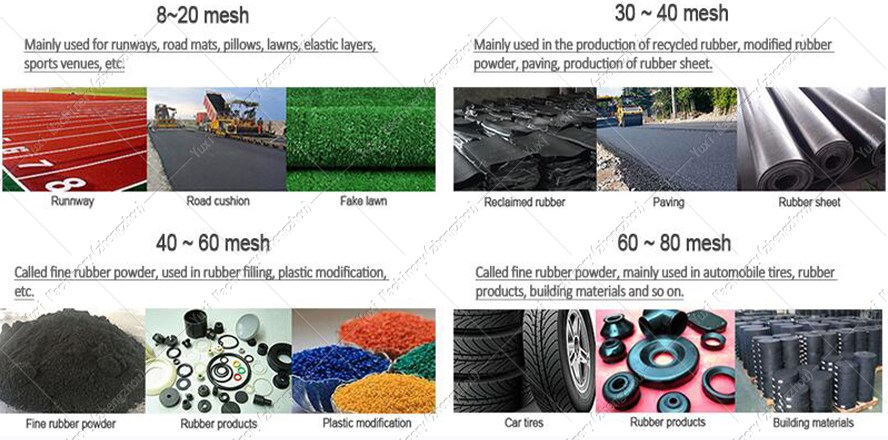

With the development of the rubber industry and the automobile industry, a large number of waste tires, rubber products and other leftover materials continue to increase. These wastes can be recycled and reused after treatment. Among them, nylon can be processed into plastic products, steel wire can be cut into steel shots or returned to the furnace for recycling, rubber can be processed into granules, and rubber powder is widely used in making various rubber products, construction, highways, railways, airports, sports fields, decorative materials, etc.

The processing of waste tires into rubber granules is either for oil refining or for making plastic track. Both rubber granules and steel wire are obtained from one waste tire processing recycling line, which not only bring environmental benefits, but also economic benefits.

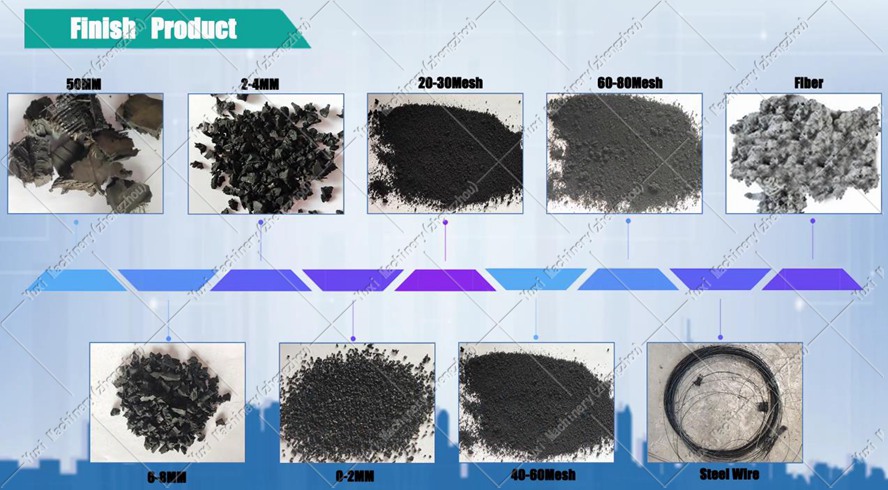

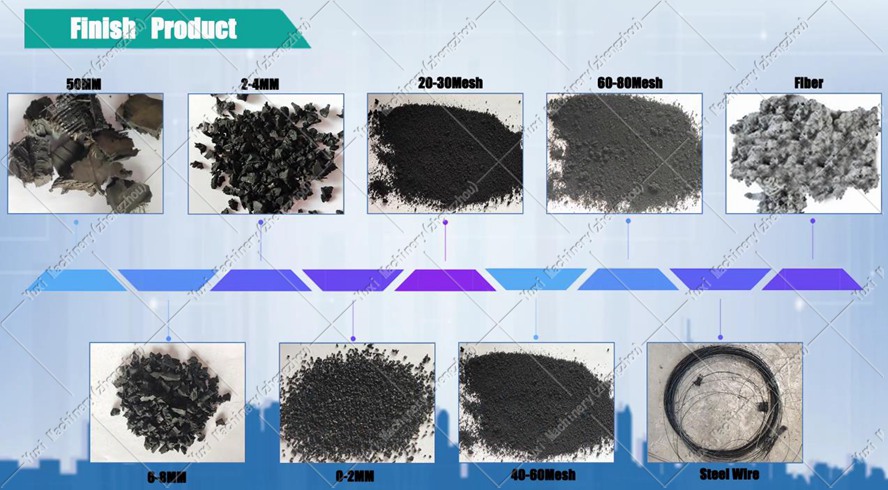

Yuxi waste tire granulator machine has two independent driving devices. The crushing chamber can work independently, and in actual production, the working system can be changed according to the material feeding amount. When material feeding is low, it works with a single driving device, and when the material feeding is large, it works with two driving devices. Yuxi waste tire granulator can be adjusted according to customers' requirement on final discharging size, and the conventional finished product specifications are 1-2mm, 3-4mm, 5-6mm. Yuxi waste tire granulating machine is suitable for processing materials with good toughness and elasticity, with advantages of no dust pollution and low noise during the crushing and sorting process.

Now the production of recycled rubber and rubber powder is very popular, and waste tires are the main raw materials for the production of recycled rubber and rubber powder. Waste tire recycling equipment can realize the value of reusing waste resources, laying the foundation for resource development, and at the same time realizing the green and regenerative cycle development of waste tires.

In the crushing of materials such as rubber and tires, two crushing methods are commonly used, namely the tire crushing granulating production line and the tire rubber powder production line. The crushing method is selected according to the material characteristics of the finished product, and the size of the finished product. Generally, the shearing and crushing method is used to process it into a uniform particle, and the multi-stage grinding method is used to produce tire powder. The finished particle size is 1-6mm; while the finished rubber powder size is 20-80 mesh. Rubber powder can not only replace part of natural rubber, but also become the main raw material for new materials such as waterproof materials, rubber runways, rubber floors, etc.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment