Waste tires are a big problem that pollutes the environment

The tire is one of the important parts of a car. For a long time, waste tire disposal and resource utilization technology has always been a worldwide problem in environmental protection. With the increase in the number of cars entering the family and the number of car ownership, the amount of waste tires is entering a rapid growth stage. How to effectively recycle tires to prevent direct pollution and secondary pollution to the environment is also an urgent problem to solve in the recycling and utilization of waste resources in the world.

Composition and recycling of waste tires

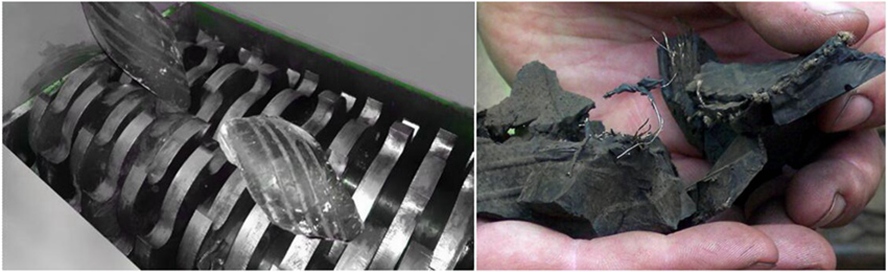

The main components of waste tires are rubber, steel wire and fiber. The recycling method is to separate the steel wire and fiber inside the waste tire through various technologies and grind the rubber block into rubber particles or rubber powder. Therefore, the utilization rate of tires reaches more than 99%, and there is no secondary pollution in the recycling process. The recycling of waste tires to produce reclaimed rubber is an ideal model that integrates environmental protection and resource reuse.

There are many ways to process waste tires, such as: retreading tires, producing tire reclaimed rubber and rubber powder, pyrolysis and incineration, etc. The least environmental pollution should be retreading tires and producing tire reclaimed rubber. According to quality of different tires, the quality of reclaimed tires produced varies greatly.

Tire wire separator/tyre rubber rasper

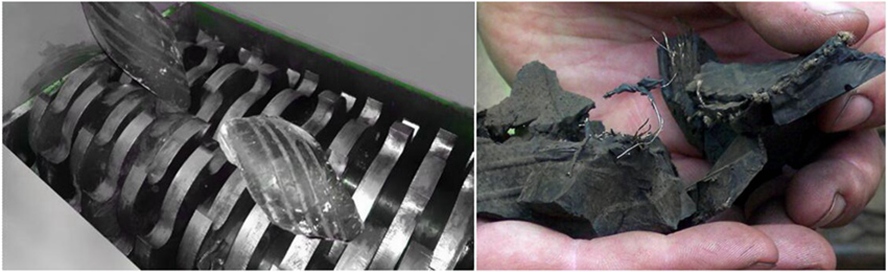

There are not only rubber, but also steel wire in tires. Therefore, when the tire is shredded, it is often necessary to cut the steel wire inside the tire together. The steel tire wire separator independently developed by Yuxi Machinery can shred the steel wires in tires at one time, secondary working process is unnecessary.

Tire wire separator is a kind of equipment independently researched and developed by Yuxi Machinery combined with practical experience in response to the current rising trend of waste tire recycling. Yuxi tire rubber rasper is composed of motor, reducer, rotating knife roller, box body, frame, screen, and a hydraulic auxiliary mechanism. The tire wire separator crushes the waste tire rubber block (50-100mm) into 15-30mm particles, and separates the steel wire and part of the fiber from the rubber during the crushing process.

The file on the rotating knife roll and the file on the box body shears and squeezes the rubber block to a smaller particle size. At the same time, the steel wire and some fibers are screened and separated from the rubber while the rubber block is broken. The bottom of the steel wire separator is equipped with a screen. The material smaller than the screen mesh will fall out through the screen; the material larger than the screen mesh will remain in the crushing cavity and be circulated and crushed again until it is crushed to be smaller than the screen mesh and falls out.

The recycling of waste tires is in line with the current sustainable development strategy. It can not only be supported by national policies, but also can take into account economic benefits. However, if you want to invest in waste tire recycling, you also need to consider the site construction, equipment technology, labor costs, water and electricity consumption, the cost of recycling waste tires in the early stage, and so on.

If you need any help, please feel free contact us, thank you.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment