Waste tyres can be cracked and refined, crushed into fuel for power generation and ground into rubber powder for recycling, all of them have become relatively popular money-making industries in the current situation of environmental protection and carbon neutrality. Tyres are mainly made up of rubber, containing materials such as steel wire, with uncomplicated components and simple recycling processes. However, to efficiently process tyres into the size you need is not easy by a general shredder.

Zhengzhou Yuxi Machinery have improved our patented twin-shaft tyre shredder, with high strength, super wear-resistant alloy steel knives and an S-shaped arrangement, the updated tire shredder is more capable of gripping and shearing different types of tyres. At the same time, in order to save users' costs, each piece of the cutter is easily removable and interchangeable, and the cutter can be repaired and reused after it wears out, extending the cutter life as much as possible.

Yuxi waste tyre shredder is designed with a rotating screen, which cleverly integrates the shredding machine and screening machine into one machine, so the simultaneous crushing and screening helps to achieve the required particle size at one time, improving processing efficiency and also reducing the space occupied, killing many birds with one stone. Yuxi rubber tire shredder is suitable for the shredding of various rubber products such as oil cartridge rubber, waste tyres and dust jackets.

How can we shred these waste tyres, waste rubber and save costs? Rubber tyre shredder is a special equipment for shredding scrap rubber tyres. Rubber shredder can be used to shred waste rubber tyres, and the size of finished products can be adjusted according to the standards of the tyre factory. Shredded rubber powder can be manufactured recycled rubber.

The scrap rubber tire shredder has a high degree of automation and high production efficiency, helping the user to use large size rubber economically and effectively. All rubber products that can be put into the feeding box can be shredded and crushed directly without cutting and decomposition. Rubber shredder also can be used for shredding and recycling waste plastics, waste rubber, wood, paint buckets, waste appliance casings (plastic and metal casings), large tyres, large nylon materials, large fishnets, large pipes, fibres, paper and other bulky waste.

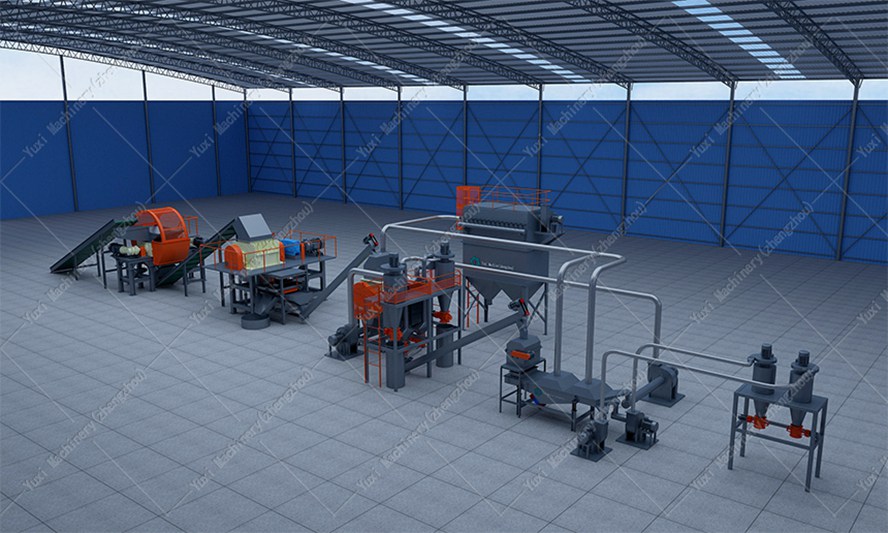

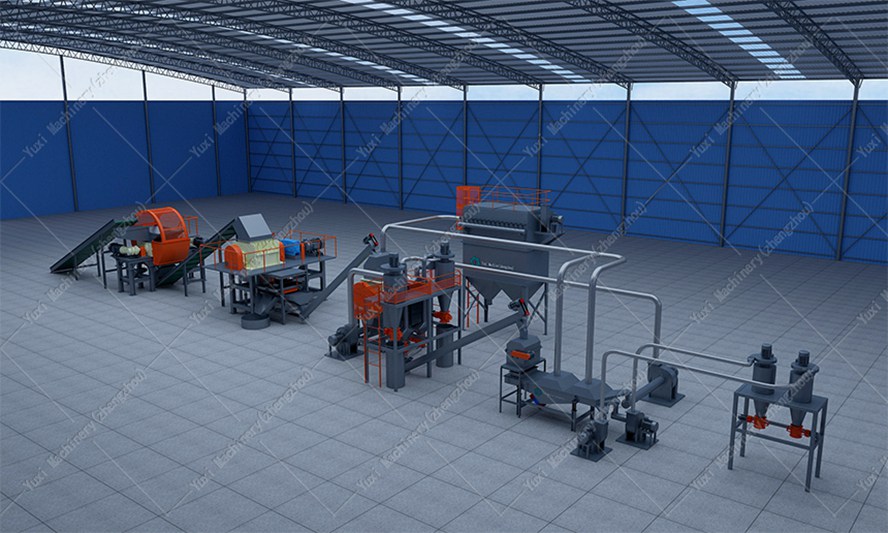

Tyre Shredder Production Line

Twin-shaft tyre shredder: pre-processes the entire tyre to a size of about 50-80mm rubber pieces.

Steel wire separator: the tyre pieces are further processed to a size of less than 20mm by means of a serrated knife. 96% of the steel wire is separated from the tyre in this step.

Magnetic separator: 99.7% of the magnetic metal is removed by magnetic separator.

Vibrating screen: the crushed material is divided into upper and lower sieves to ensure the purity of the latter sorting process.

Electrical control system: strong cutting-off capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, etc.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment