Waste lithium batteries contain a large amount of metal resources with high economic value and high use value, and the positive and negative electrodes of lithium batteries contain a large amount of metal materials such as nickel, copper, and molybdenum. Lithium batteries can be divided into many categories, with copper and aluminum pole pieces, with dry separator black powder aluminum pole pieces, black powder and aluminum pole pieces, etc. Different types of lithium batteries need to be processed in different ways.

Introduction of Yuxi Pole Piece Processing and Recycling System

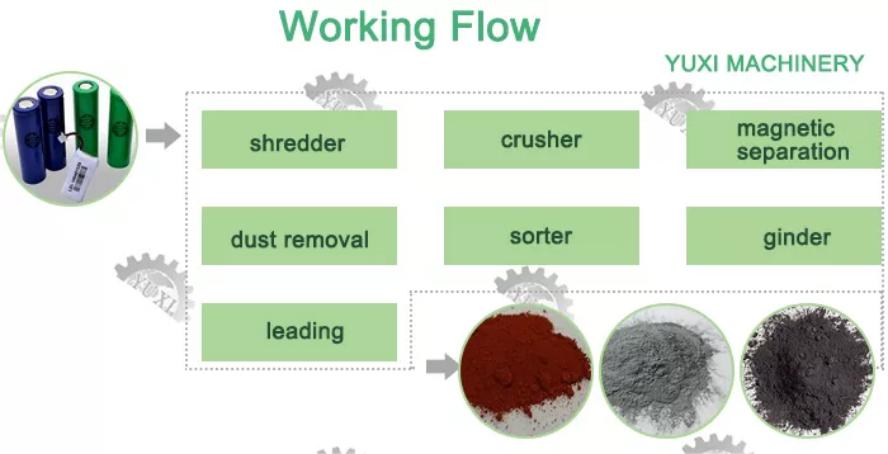

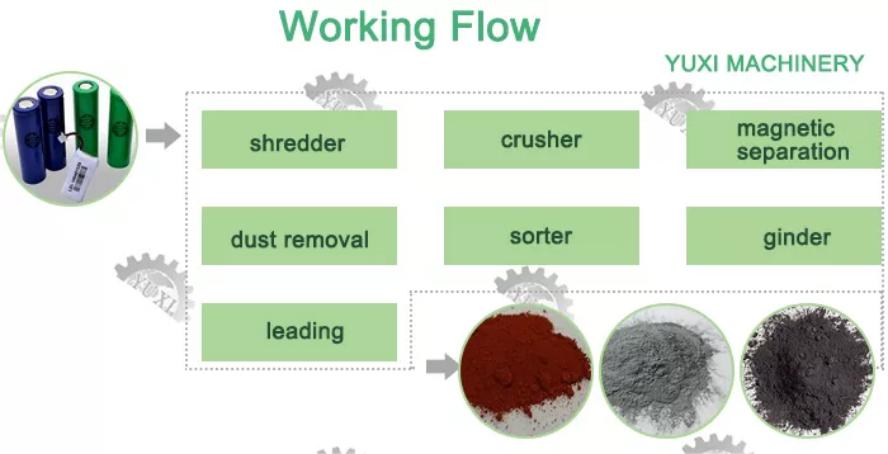

Yuxi lithium battery recycling and processing equipment includes primary crusher, conveyor, crusher machine, material breaker, negative pressure pumping device and sorting device connected in sequence. The discharging end of the conveyor is equipped with magnetic roller to absorb the iron particles in the material. The sorting device is used to sort out the mixture of black powder and aluminum, and the diaphragm with black powder attached to the surface. The discharging port of the sorting device is connected with negative pressure pumping device, sorting device and powder removing machine in sequence. Among them, the sorting device is used to separate the diaphragm from the black powder attached to the surface of the diaphragm; the other outlet of the sorting device is connected with conveyor, crusher and sorting device in sequence, wherein the sorting device is used to separate the black powder and aluminum.

Sorting Effect of Iron and Lithium Pole Pieces of Waste Lithium Battery Recycling Equipment

● Black powder recovery rate ≥ 99%, including recovery by dust collection equipment

● Aluminum recovery rate≥99%

● The purity of aluminum ≥ 98%, containing a small amount of diaphragm and hard plastic

● Black powder purity ≥ 99%

● Impurities in aluminum powder ≤ 1.5%

● Black powder in aluminum ≤1%

● Dust particles <10mg/m3

● Equipment noise ≤75dB

● Recovery rate of nickel-containing substances is ≥98%

Negative Electrode Powder Removal Effect of Lithium Battery Recycling Machinery

● Recovery rate of black powder ≥ 99%

● Recovery rate of copper ≥ 99%

● Copper purity ≥ 98%

● Impurity rate, copper in black powder ≤0.5%

● Black powder in copper ≤1%

Yuxi lithium battery recycling and processing equipment can automatically process the positive and negative electrodes, with a high degree of automation and low labor costs. Yuxi lithium battery pole piece processing and recycling system separates the black powder, aluminum and diaphragm, so as to recycle the black powder, aluminum and diaphragm separately. Moreover, the advanced sorting equipment can separate the diaphragm and a small amount of black powder attached to its surface, thereby improving the recovery rate of the black powder and meeting the demand for non-ferrous metals in the development of new energy.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment