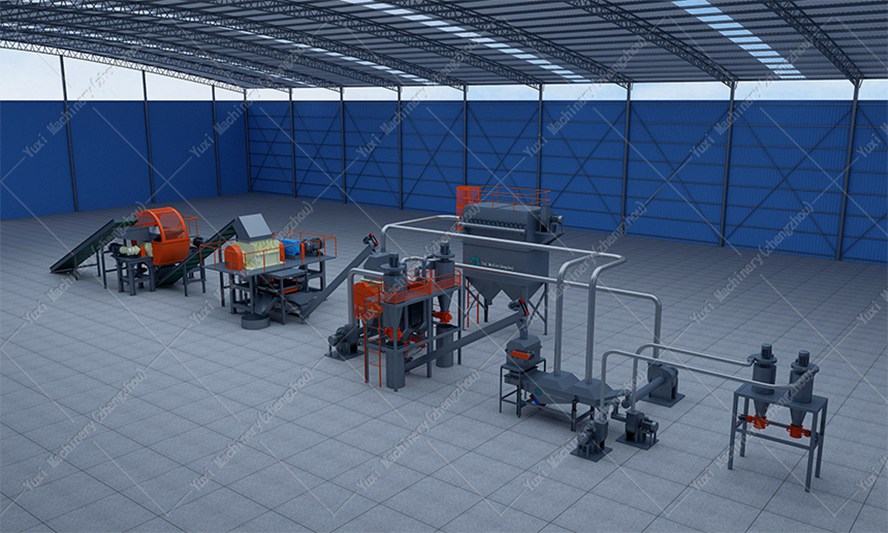

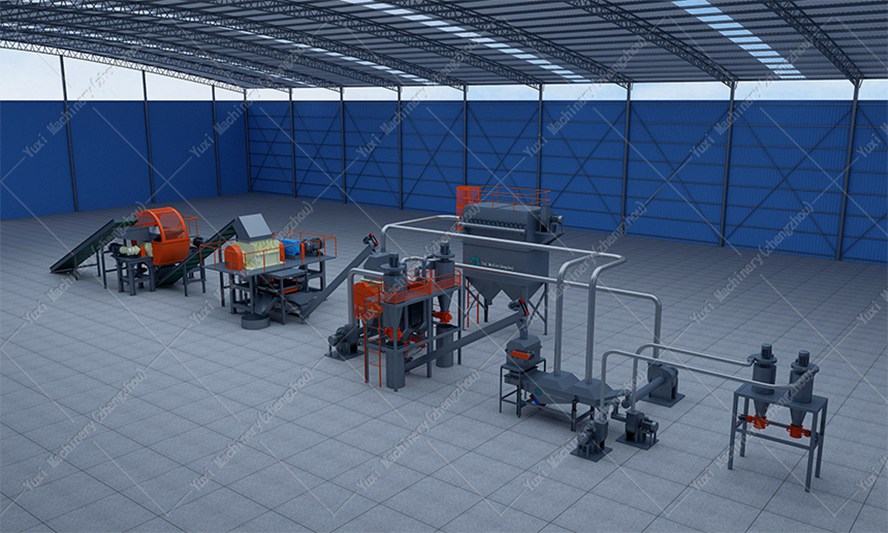

The utilization rate of on-site recycling of waste tires is high, which is also the reason why the application fields of waste tire processing recycling equipment are becoming wider and wider. According to production capacity and different requirements for finished products, our company has launched new waste tire processing production line. Yuxi complete set of waste tire processing equipment can be configured into different combinations according to the needs, so as to meet the requirements of different corresponding process and production scale.

Waste Tire Crushing Pretreatment

After the waste tires wires are drawn by the tire wire drawing machine, the thicker steel wires on both sides of the hub are extracted, and then the tires without wires are transported into the double-shaft tire shredder by the heavy metal chain conveyor. The rotor in the shredding box is driven by the motor + reducer. With the working principle of low speed and high torque, the tires are crushed and cut into pieces. The outer side of the waste tyre shredder is surrounded by a ring drum screen. The tire rubber blocks cut into small pieces fall on the roller screen, the rubber blocks smaller than the aperture of the screen are fed to the output device for the next step, and the rubber blocks larger than the aperture of the screen are returned to the crushing box for further secondary shredding. The crushed rubber blocks are discharged from the discharge belt conveyor, and the final discharge is directly sent to the cracking and refining equipment.

Waste Tire Pyrolysis Process

After the waste tires are crushed, they are sent to the cracking furnace for catalytic heating, so that they are cracked into cracked gas and cracked distillate oil, and at the same time, they react to form carbon black. Further fractionation of cracked distillate oil can obtain gasoline, diesel oil and heavy oil, and the solid waste generated in this process is carbon black, which will reach the standard of industrial raw materials after processing. The waste gas is a non-condensable combustible gas, which will be recovered to provide heat for the entire production process and generate electricity, which not only eliminates waste gas pollution, but also saves a lot of fuel. The entire pyrolysis process is carried out in a closed environment to minimize the leakage of pollutants.

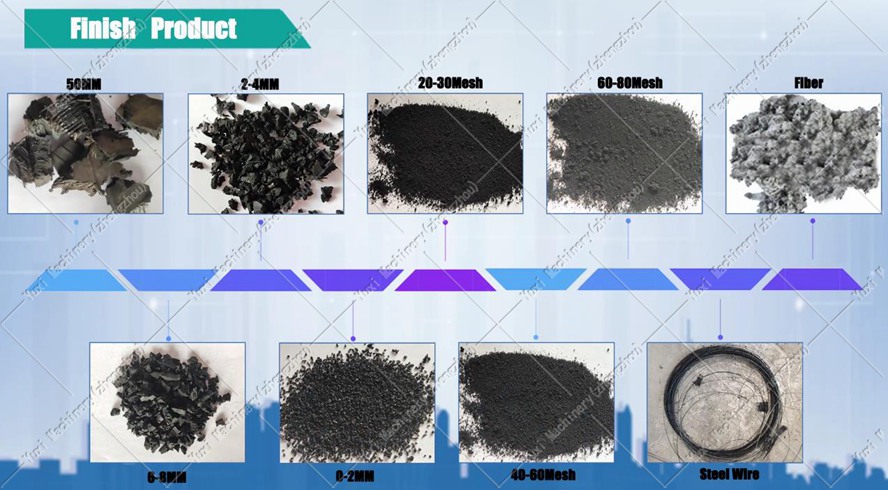

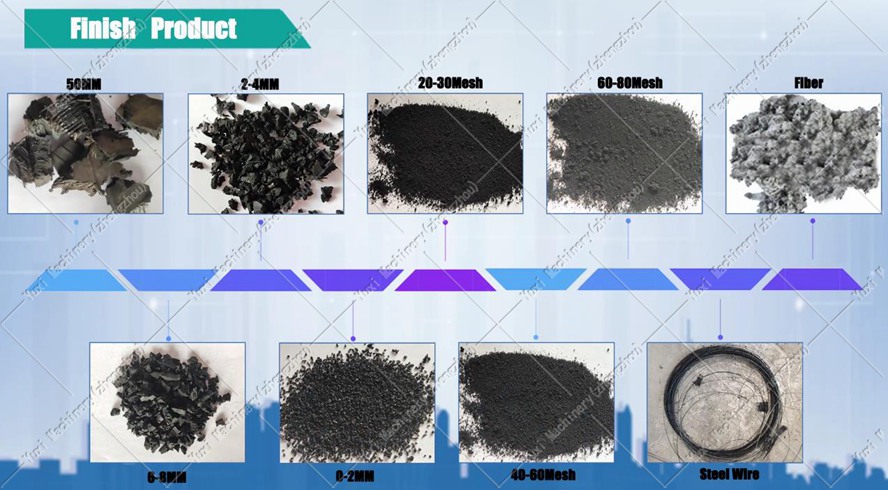

Waste Tire Crushing and Grinding Line

It is better to turn waste tires into treasure, and it is better to use it for investment to generate value and benefits. The waste tire processing recycling equipment is in a stable development stage, and the domestic global market is suitable for investment in waste tire processing equipment projects. In the field of rubber and waste tire recycling, the physical shredding and crushing technology is used to crush and reprocess waste tires, mainly using the technology of tire crushing and granulating line and tire rubber powder line as the main environmental protection equipment. Yuxi waste tire processing and recycling plant can grind various tires and various waste rubber products or leftovers to process them into rubber powder with a mesh size of 20-60 or 1-6mm.

Yuxi waste tire processing production line is customized according to the actual needs of customers, and the output size can be controlled. The entire production line is equipped with a unique GI intelligent detection system, which can realize automatic and intelligent production, only 1 to 2 operators are needed. The crushing efficiency is high, and the whole production line is highly automated and intelligently controlled, ensuring the energy saving, high efficiency and safety of the entire processing process.

How to make good use of waste rubber products and waste tires is also an important measure to protect the ecological environment and promote sustainable development. Therefore, the waste tire rubber recycling industry will surely occupy the market.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment