Introduction to Metal Baler

The fully automatic scrap metal baler is a special equipment for compressing and packing waste metal, paper, plastic and carton boards in the garbage disposal and waste recycling industries. The waste metal baling machine can maximize the compression and packing of light material waste, to reduce the footprint and transportation cost. The fully automatic metal baler can minimize investment costs and operating costs, significantly reduce waste transportation and storage costs, and improve enterprise economic benefit. The technical level of the metal baler machine has reached the leading position in China, filling the gap of similar products in this field.

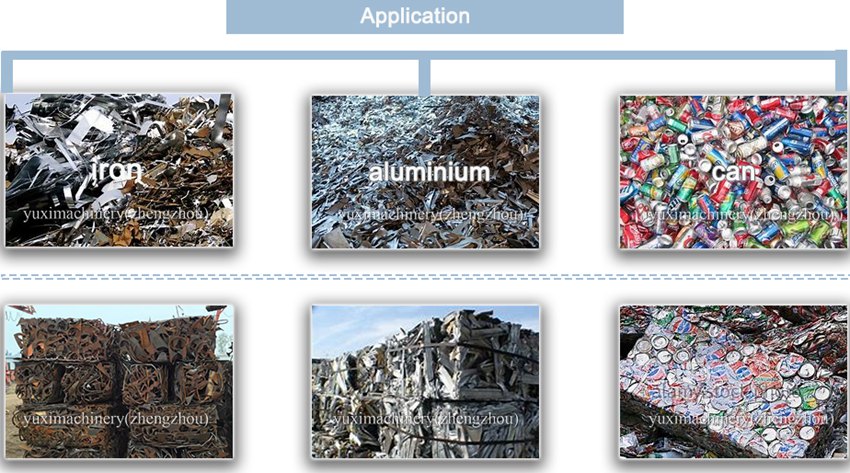

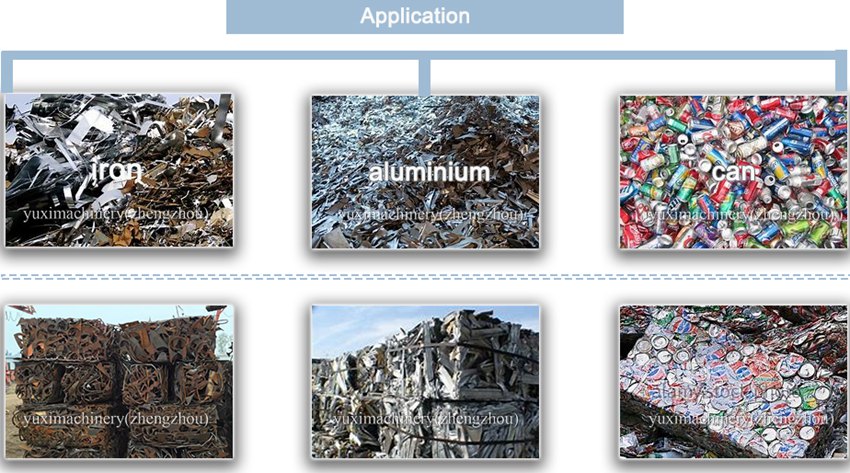

Application of Hydraulic Metal Baler Machine

Hydraulic metal baler is mainly suitable for steel mills, recycling and processing industries, and non-ferrous and ferrous metal smelting industries. Waste metal, waste plastics, waste fabrics, wheat straw, cotton, straw, grains and other items can be compressed and packaged by metal baling machine, which is convenient and can reduce storage space, improve labor efficiency, reduce labor intensity, save manpower and transports.

Other Application of Hydraulic Metal Baling Machine

Yuxi hydraulic metal baler is strong and firm, economical, practical, easy to operate, safe and reliable, with characteristic of tight structure, etc., is an ideal equipment for material packaging, waste recycling and other industries. The hydraulic baling machine can squeeze all kinds of metal scraps (steel shavings, scrap steel, scrap aluminum, scrap copper, scrap stainless steel, scrap car scraps, etc.) into qualified furnace charge with various shapes such as cuboid, octagon, and cylinder. Yuxi hydraulic metal baler can not only effectively reduce the cost of transportation and smelting, but also increase the speed of furnace.

Features of Hydraulic Metal Baler

1. The metal baler is hydraulically powered, easy to install, and no foundation is required.

2. No foot screws are required for installation. Diesel engines can be used as power in places where there is no power supply.

3. There are different discharging ways, such as turning over, pushing, or manually picking up (packing).

4. Joystick operation is safe and reliable.

5. The size of the machine and the size of the bale can be customized according to customer requirements.

6. The pusher cylinder and the pusher head are connected by a spherical structure, which has good reliability and long service life of the oil seal.

7. The feeding port is widened and enlarged, and the filling is more convenient and quick.

8. Low noise hydraulic circuit , high efficiency and low breakdown.

Scrap Metal Baler Manufacturers

The horizontal baler is designed with full consideration of human operation safety. There are protective nets and safety switches in dangerous parts, and an emergency stop button is designed to ensure personal safety.

Parameter

| Model | YXJD-63 | YXJD-100 | YXJD-125 | YXJD-400 |

| Pressure(KN) | 630 | 1000 | 1250 | 4000 |

| Packing Dimension(mm) | 1000*600*500 | 1000*700*550 | 1200*700*600 | 3000*2000*1200 |

| Size(mm) | 190*190 | 230*230 | 300*300 | 500*600 |

| Weight(kg) | 15~30 | 30~40 | 50~75 | 250~380 |

| Capacity(t/h) | 0.4~0.8 | 0.6~1.2 | 1.2~1.5 | 6.8~8.0 |

| Power | 7.5 | 11 | 15 | 45*2 |

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment