Introduction to Aluminum Plastic Separator Machine

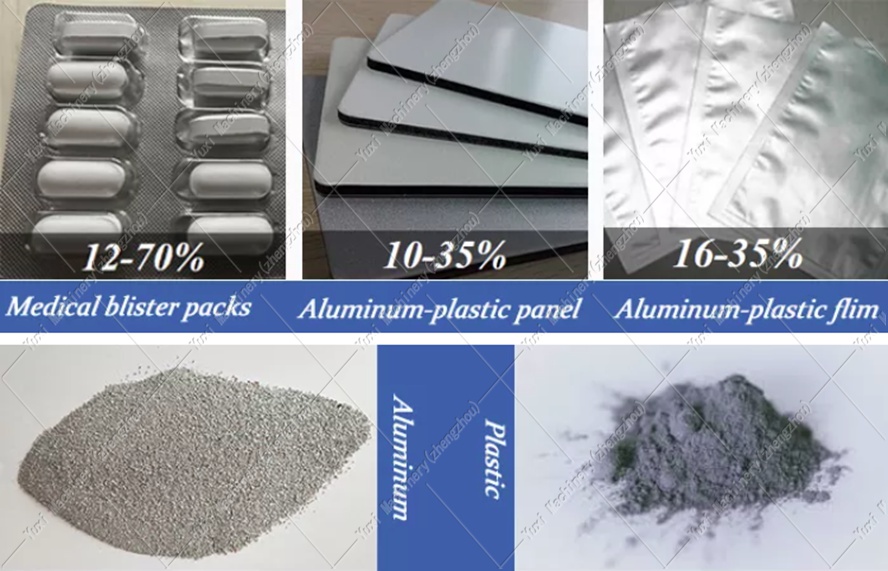

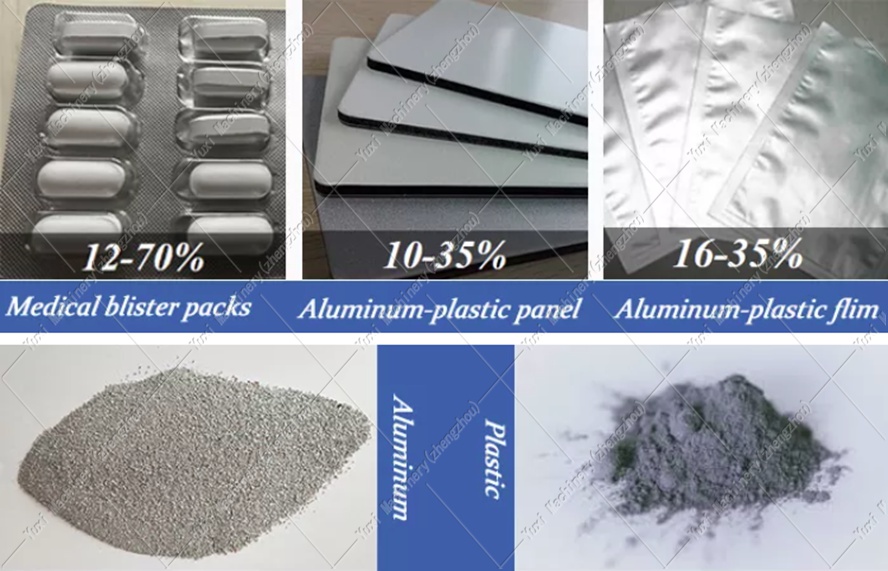

Aluminum plastic separator adopts physical separation method to separate all kinds of aluminum plastic board, waste plastic aluminum, medical blister, aluminum-plastic plate, aluminum composite panel, food packaging bags, toothpaste tubes, plastic bottle caps, leftovers and pieces of plastic aluminum board.

Working Principle of Aluminum Plastic Sorting Machine

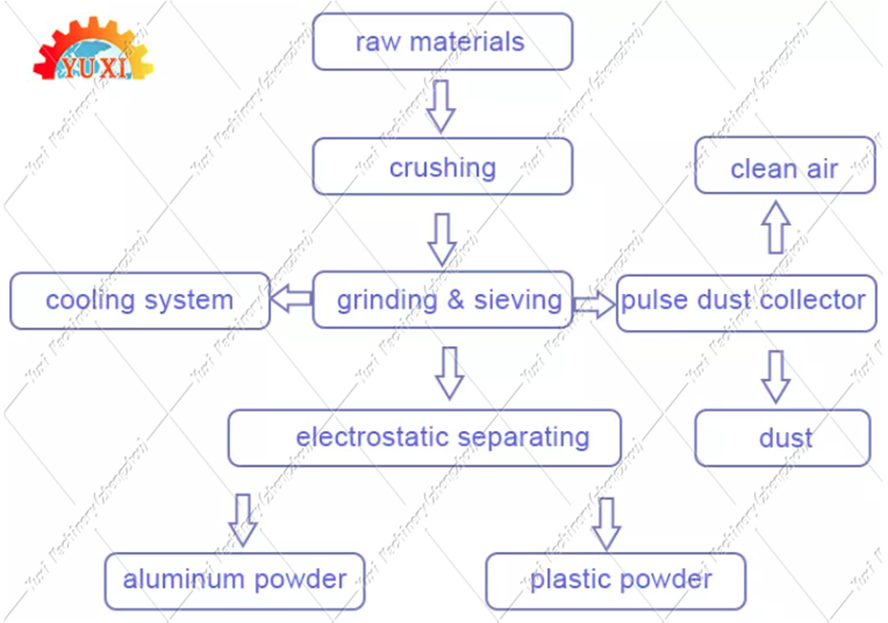

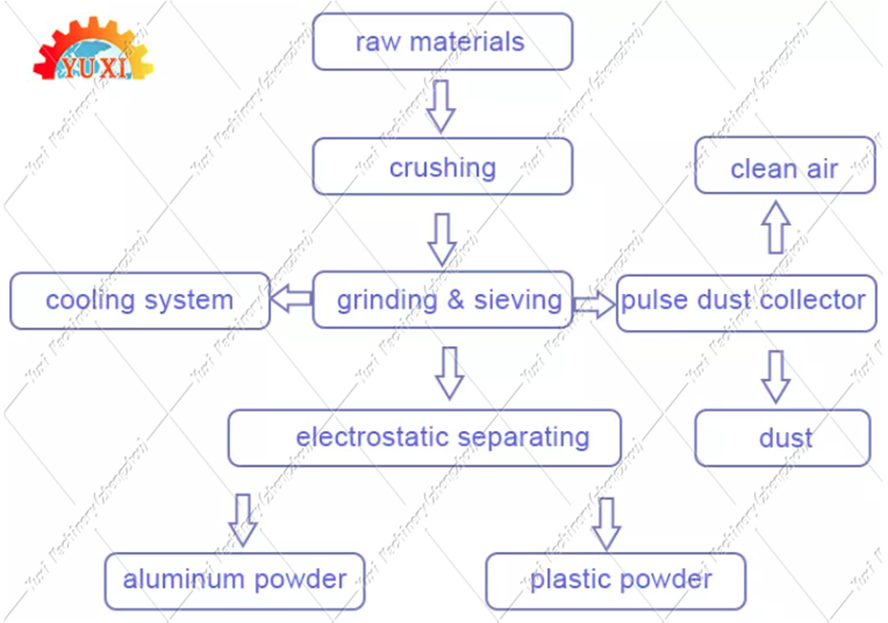

Firstly, the crusher crushes the aluminum plastic plate into 0.5cm pieces, then the grinding mill grinds the material into powder, then the circular vibrating screen screens the powder into different sizes. The powder in suitable size will be delivered to the electrostatic separator. The electrostatic separator can separate the aluminum and plastic in 99.9% rate. The whole process can be realized in one production line, fully closed operation will not create any pollution.

Application of Scrap Aluminum-Plastic Recycling Line

Waste PCB materials can be recovered to copper-based precious metal mixtures and non-metallic powder mixtures through physical processes such as tearing, rough breaking, crushing, air flow sorting, vibration gravity separation, static sorting, etc. Waste aliminum-plastic materials can be recovered to pure aluminum and plastic with the help of waste aluminum-plastic recycling machine. Dust and exhaust gas produced in the production process are collected in an orderly manner and do purification treatment before discharging.

Advantages of Aluminum-plastic Sorting Line

1. High automation program, simple operation and stable performance;

2. High-voltage electrostatic separation efficiency of 99%, the finished product can be sold directly;

3. No waste water exhaust, real green environmental sorting, no secondary pollution;

4. Low power consumption, low noise, small floor space, no powder pollution;

5. Wide range of sorting materials, fast sorting speed;

6. The aluminum-plastic sorting and reusing equipment adopts water-cooled and air-cooled turbine grinding machine, which makes the separation more clean and produces a wider variety of materials.

Process of Aluminum-plastic Separating Line

Shredder (for choice) - crusher--grinding machine - electrastatic separator - pulse dust collector

Output is aluminum granules or powder ( 15-25meshes) and plastic granules/powder

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment